Client

Georgia Power Company

Project Location

Forston, GA

Timeframe

2011-2018

Sustainable, Reliable, and Efficient

This project was a collaborative effort with notable contributions from Cianbro, Keystone Industrial, Alignment Services of North America, Powerhouse Mechanical Repairs, Glenn Underwater Construction Services, and G&A Consulting Engineers. Embracing LEAN construction practices, the team fostered a culture of continuous improvement, enhancing safety, quality, and productivity throughout the two-year construction phase.

Enhanced Operational Efficiency and Reliability:

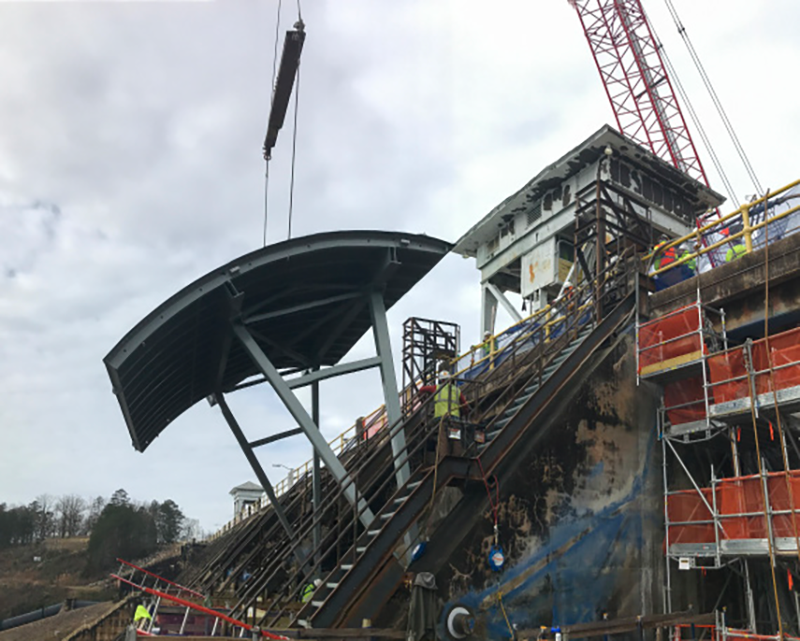

The replacement of the 21 spillway gates and the introduction of new 20-ton gantrycrane-type gate hoists have significantly upgraded the plant’s operational efficiency.

Expanded Infrastructure Lifespan:

Through meticulous engineering and the replacement of aging infrastructure with state-of-the-art components, the plant’s operational lifespan has been significantly extended.

Cost Savings and Risk Mitigation:

Innovative prefabrication and pre-assembly of spillway gates provided substantial cost savings to Georgia Power Company.

Setting Industry Benchmarks:

The scale, scope, and innovation demonstrated in this project have garnered national attention, positioning the client at the forefront of sustainable energy practices.